Our modern world is determined by a booming haulage and transportation to help keep modern societies mobile and provided with their every need. There is one product that is an important constituent of all of transportation whether they are busses, semi-trucks, SUVs, mopeds or bicycles –– tyres. Tyres of any size and dimensions are used on their last surviving tread, and definitely will all eventually head to the landfills and refuse deposits around the globe –– when we are lucky!

The truth is, many landfills in environmentally conscious nations will no more accept tyres in landfills and waste dumps as they are not much of a “disposable” item. Tyres still carry chemical compounds along with other constituents that will make them unhealthy to the environment. Unfortunately, recycling plants are unable to cover the whole quantity of discarded tyres and sadly many will land in the rivers and oceans where their toxins leach out to the environment and cause more problems.

Fortunately, innovative tyre pyrolysis machine manufacturers in China have designed a suitable means to fix this considerable problem to the need for waste management solutions.

Truth be told, regardless how threadbare your tyres may seem there is certainly still lots of good within them, if you have the equipment and know-the best way to access the valuable sequestered within your average tyre. Following is an introduction to one such solution.

The benefits of a Pyrolysis Plant by Manufacturers

Millions and millions tyres are now being discarded everyday throughout the world and it was only dependent on time toil someone figured that it abundant waste also represents and considerably valuable sustainable resource.

On one side, waste tyres produce a problem as they are able lie around littering vacant lots and form a great breeding ground for disease carrying mosquitos. But with the effective use of the correct equipment, these tyres may be put to great use again. Click here to know more: https://bestonpyrolysisplant.com/.

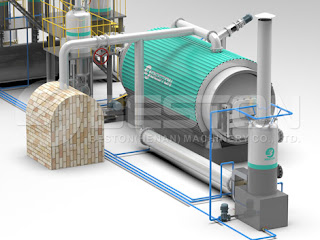

Tyre pyrolysis plant manufacturers in China have produced a suitable solution that requires transforming these wasted tyres into products which are useful and profitable. The phrase “pyrolysis” actually way to be transformed through fire and describes the chemical transformation of things burned in low-oxygen conditions.

You almost certainly there exists more inside a tyre than there are actually within your average rubber ball. Actually, almost 40% in the tyre contains materials that may be salvaged and repurposed.

The Pyrolysis Process

A tyre pyrolysis plant crafted by reputable manufacturers in China features a professional design. Inside the tyres as well as their constituents will be susceptible to high temperatures and you will be turned into marketable products.

The evaporated constituents in the tyres as an example might be collected in the condensing chamber and transformed into an oily substance called “syngas”, which has applications inside the fuel industry. Furthermore, steel is another ingredient in many tyres and might be extracted and returned to the scrap metal industry. Get tyre pyrolysis plant cost here.

Final Notes on Tyre Pyrolysis

While the tyres we use for travel and transport might cause a significant waste management issue, you can find choices to individuals with a mind for business. A pyrolysis plant allows the entrepreneur to close the web link between waste tyres and new profitable products. Visit the site: https://bestonpyrolysisplant.com/waste-tyre-recycling-plant-price/.